How Brands Can Boost Sales by Auditing and Fixing Customer Product Pages

Catalog managers understand the importance of accurate product data, but maintaining precision across multiple retailers is a daunting task. You craft compelling product content to outshine competitors, yet errors like incorrect images, missing details, or wrong fitment information often appear on retailer sites. Worse, these issues sometimes reach your boss’s inbox, causing embarrassment and frustration.

While perfection is elusive, you strive to make your data as accurate as possible. Larger teams might have resources for audits, but smaller teams often send files and hope for the best. Unfortunately, hope isn’t enough.

==> Original research by Bridge Below at ACPN 2025 revealed that 58% of 80,000 SKUs checked had at least one error or significant deviation from the sent files.

So, what can small to medium aftermarket auto parts manufacturers do? Let’s explore three common problems and practical solutions.

1. Returns from Fitment Errors—And Why They Happen

Fitment-driven returns are among the costliest and most frustrating issues in the aftermarket industry, yet they’re often avoidable. Customers return parts they believe don’t fit, whether due to actual misfit or misleading information.

Why This Happens

- Resellers display stale or incomplete fitment data.

- Your ACES file is accurate, but it wasn’t used.

- You updated the file, but the reseller hasn’t applied the changes.

Somewhere between your system and theirs, incorrect applications get attached.

The Damage

- Returns erode margins with shipping, restocking, and processing costs.

- Buyer confidence wanes.

- Both your brand and the reseller’s take a hit.

What You Can Do

Spot-check your most-returned SKUs on key reseller sites. Verify if fitment applications match your source file and are present.

Spot-check your most-returned SKUs on key reseller sites. Verify if fitment applications match your source file and are present.- Keep a simple change log tracking when fitment data was updated and to whom it was sent.

- Provide resellers with a concise “Fitment QA Checklist.”

- Pro Tip: Focus on high-volume parts driving most returns. Ensure their fitment data is correct on major sites.

Pros: Even minimal auditing is better than none, and some PIM systems may maintain change logs for you.

Cons: Manual spot-checking is time-consuming and limits coverage to a few SKUs.

2. Top SKUs Vanish from Reseller Sites Without Notice

It’s painful to discover that your top-performing parts are missing from retail or distribution channels. Often, no one knows when or why they disappeared.

Why This Happens

- Feed errors or ingestion failures silently remove products.

- SKU logic changes (e.g., prefixes or availability flags) are misread.

- Reseller bulk updates overwrite or delete your content.

The Damage

- Lost sales, especially for high-priority products.

- Wasted ad spend on dead links, harming customer experience.

- Urgent “fire drills” to restore listings.

What You Can Do

- Monitor sales numbers for key SKUs by site to detect anomalies.

- Create a Google Sheet listing your top 100 SKUs and their URLs. Check monthly, if not blocked by site protections.

- Develop a disaster action plan with each reseller.

- Pro Tip: Include product visibility checks in your new product launch checklist to ensure new SKUs go live correctly.

Pros: Proactive monitoring provides early warnings, and recovery plans can expedite fixes.

Cons: Many sites block automated checks, and manual solutions are labor-intensive. Simply confirming a page exists doesn’t ensure its accuracy (e.g., correct price or details).

3. Inaccurate Reseller Pages—And the Challenge of Fixing Them

You notice missing images, outdated bullet points, or irrelevant copy on reseller sites, but auditing and correcting every listing feels overwhelming.

Why This Happens

- Clean data is sent, but no one verifies what’s displayed.

- Accuracy is assumed until complaints arise.

- Auditing every SKU on every site is resource-intensive.

The Damage

- Customers abandon incomplete or low-quality listings, leading to invisible lost sales.

- Valid, in-stock products underperform.

- Competitors with sharper listings gain an edge.

What You Can Do

- Support resellers by being their easiest manufacturer to work with, prioritizing your issues.

- When auditing, provide structured fixes alongside identified issues.

- Analyze audit results for trends (e.g., consistently incorrect fields like images or fitment) to pinpoint upstream reseller issues.

- Pro Tip: Frame audits as collaborative solutions, not problems, to foster productive conversations with resellers.

“As someone on the receiving end of this process, I can’t emphasize enough how impactful it is when manufacturers and suppliers go the extra mile to understand what’s happening beyond their operations. When they take the initiative to explore the production side and audit how parts are represented on our end, whether through store systems or online platforms, it demonstrates a level of commitment that truly stands out.

This effort isn’t just about reducing returns, although that’s certainly a major benefit. It’s about creating a more seamless, accurate, and trustworthy experience for everyone involved, especially the customer. When product managers are equipped with real-world insights from both ends of the supply chain, the data transforms from abstract numbers into meaningful, actionable information that reflects actual needs.

In today’s omnichannel environment, where customers often complete their research before ever stepping into a store, this kind of collaboration is more important than ever. It doesn’t just help keep parts moving, it builds confidence, fosters loyalty, and strengthens the entire ecosystem.”Derek Acosta, Senior Manager Catalog and Content, AutoZone

The Common Thread… These issues stem from a lack of visibility into what’s happening on reseller pages. You assume sent files are used, products stay live, and listings are accurate—but assumptions aren’t a strategy.

The Solution: Practical Auditing

Auditing doesn’t require complex data governance frameworks. It’s about comparing what should be shown versus what is shown. Many believe auditing is too costly, technical, or slow, but that’s a myth.

The Truth

- No need for custom scraping systems.

- No expensive enterprise subscriptions required.

- Auditing a subset of SKUs can yield significant value.

Focus on key SKUs at priority resellers, checking critical data like fitment, images, titles, pricing, and availability. Start manually if feasible, or use affordable tools for larger catalogs to audit efficiently.

Where to Start

Take these three steps today:

- Audit your top 20 most-returned SKUs to ensure fitment data matches your files.

- Check a high-volume reseller to confirm your top 50 SKUs are live and accurate.

- Create a “content completeness” scorecard for 50 products, evaluating images, titles, and key attributes.

Expect to uncover issues—that’s not failure, it’s the first step to improvement.

Automating the Process

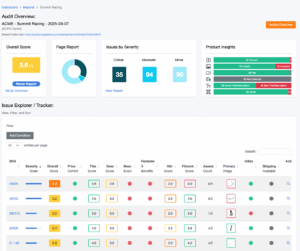

For lean teams, manual audits may not scale. That’s why we’ve developed True View Audit, a practical solution that uses your ACES and PIES files to check:

- Are SKUs present on reseller sites?

- Are all fields displayed?

- Are fields accurate?

Priced at cents per SKU, it delivers automated reports with insights, actions, and suggestions to share with retail partners. You simply accept or reject flagged issues.

Addressing Common Concerns

- “I don’t have time”: Reports are automatic, requiring minimal input.

- “I can’t afford auditing”: Flexible plans fit your budget and cadence, at least one-third cheaper than alternatives, with more comprehensive checks.

- Pro Tip: Pitch auditing as ROI-positive. Calculate how many additional sales or avoided returns justify the minimal cost.

Get Started for Free

We’re confident you’ll love our auditing solution, so we’re offering new customers a free audit of their top 100 SKUs on two reseller sites, no strings attached.*

- Send us your files (NDAs available) or contact us as a receiver.

- Specify which sites to audit.

- Receive a detailed report with a data dashboard, scorecard, insights, and action plan.

*Terms and conditions apply.

Take control of your product data today and turn assumptions into actionable insights.

Contact Us Today!